Achieve the perfect insulation value with Polyamide strips

Keep the heat inside and the cold outside? Then well-insulated aluminium profiles are indispensable. There are various insulation techniques for insulating aluminium profiles. Rolling in with Polyamide strips is one of these techniques.

Optimize insulation value with Polyamide strips

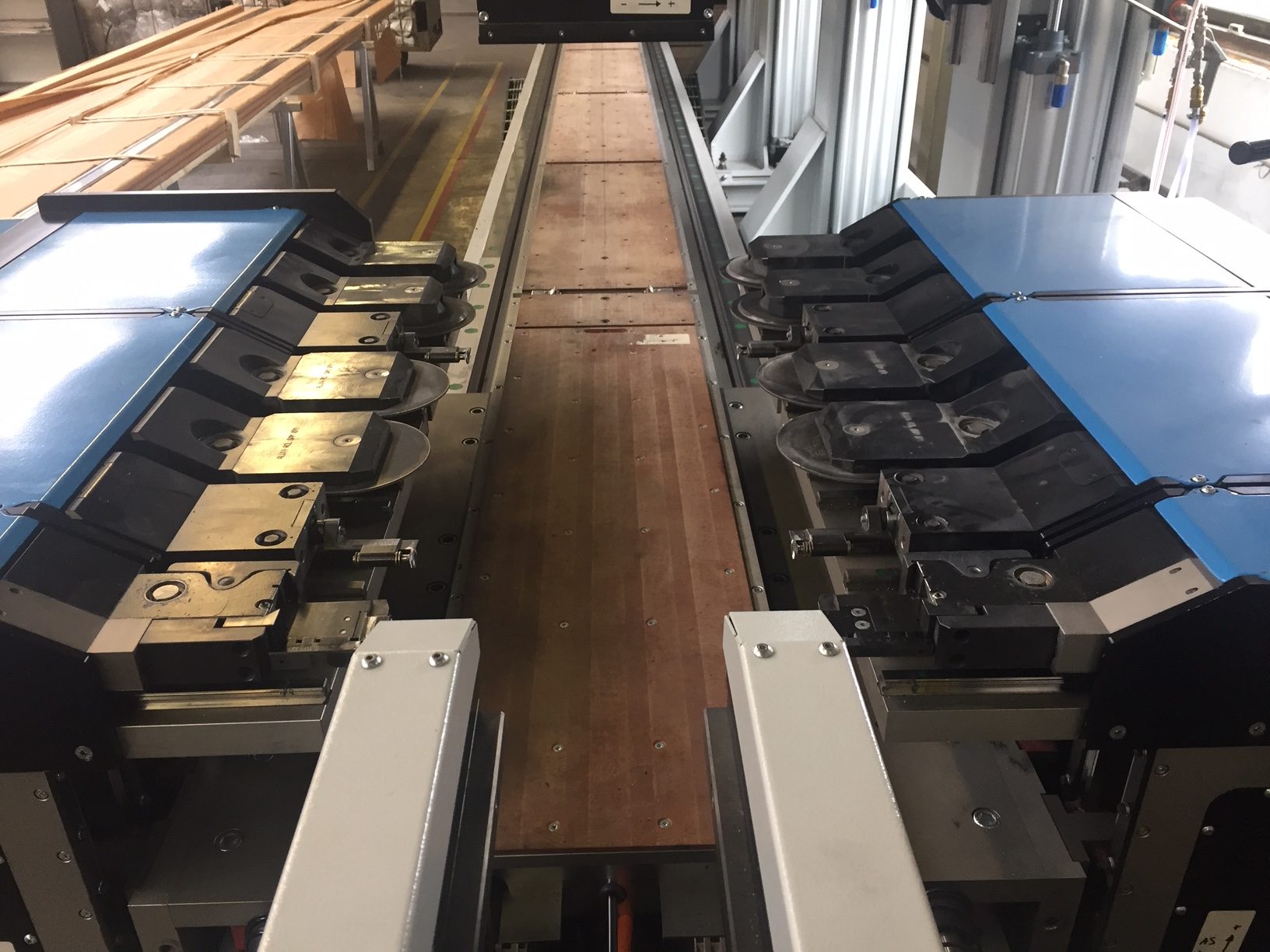

Insulating aluminium profiles with Polyamide strips is called “rolling in”. When rolling in, we do not insulate the aluminium profiles with Polyurethane resin, but with Polyamide strips. The aluminium is separated from each other by Polyamide strips. After rolling in, the aluminium profile consists of three layers: aluminium, insulation (Polyamide strips) and another layer of aluminium.